|

With the team at Respira Labs, we are developing a novel device that will help patients with COPD monitor their condition.

We are developing ultrasound technology that can capture the resonance inside the lungs. by analyzing this resonance we can find the volume of air in the lungs at any time during the breathing cycle.

|

|

|

I have been involved in the project since the very beginning. I have lead the Design and prototyping of the devices as well as the UX during testing and future UX when we release this device to the public. I play a key role in the development of the start-up.

|

|

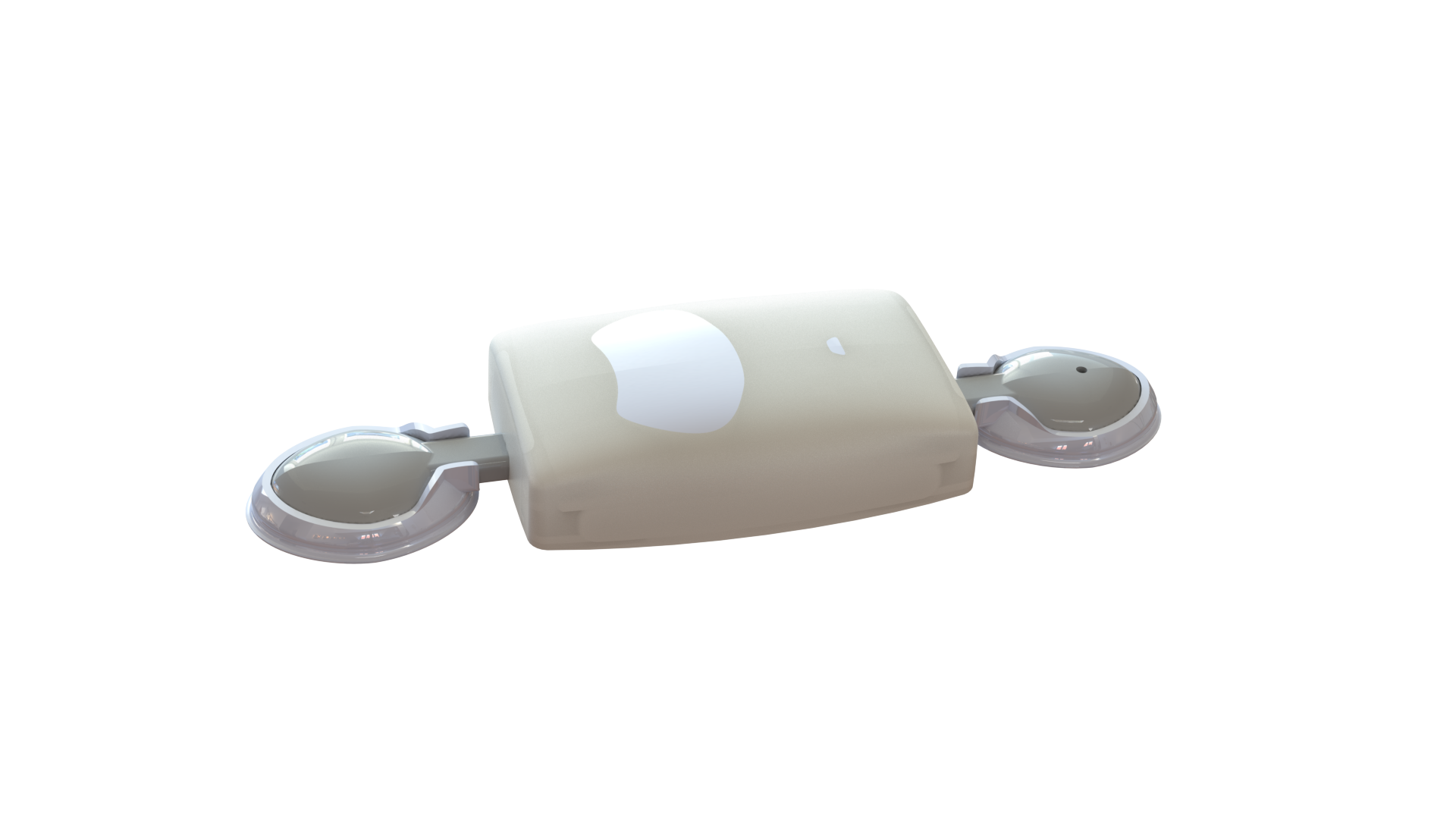

Latest Device - Version 6.2 (as of 10/2/2021)

This is a complex device with many parts and small tolerances. I have designed the prototype for 3D printing while we are on the testing phase, but all the design decisions are anchored in being able to be manufactured in the future.

|

|

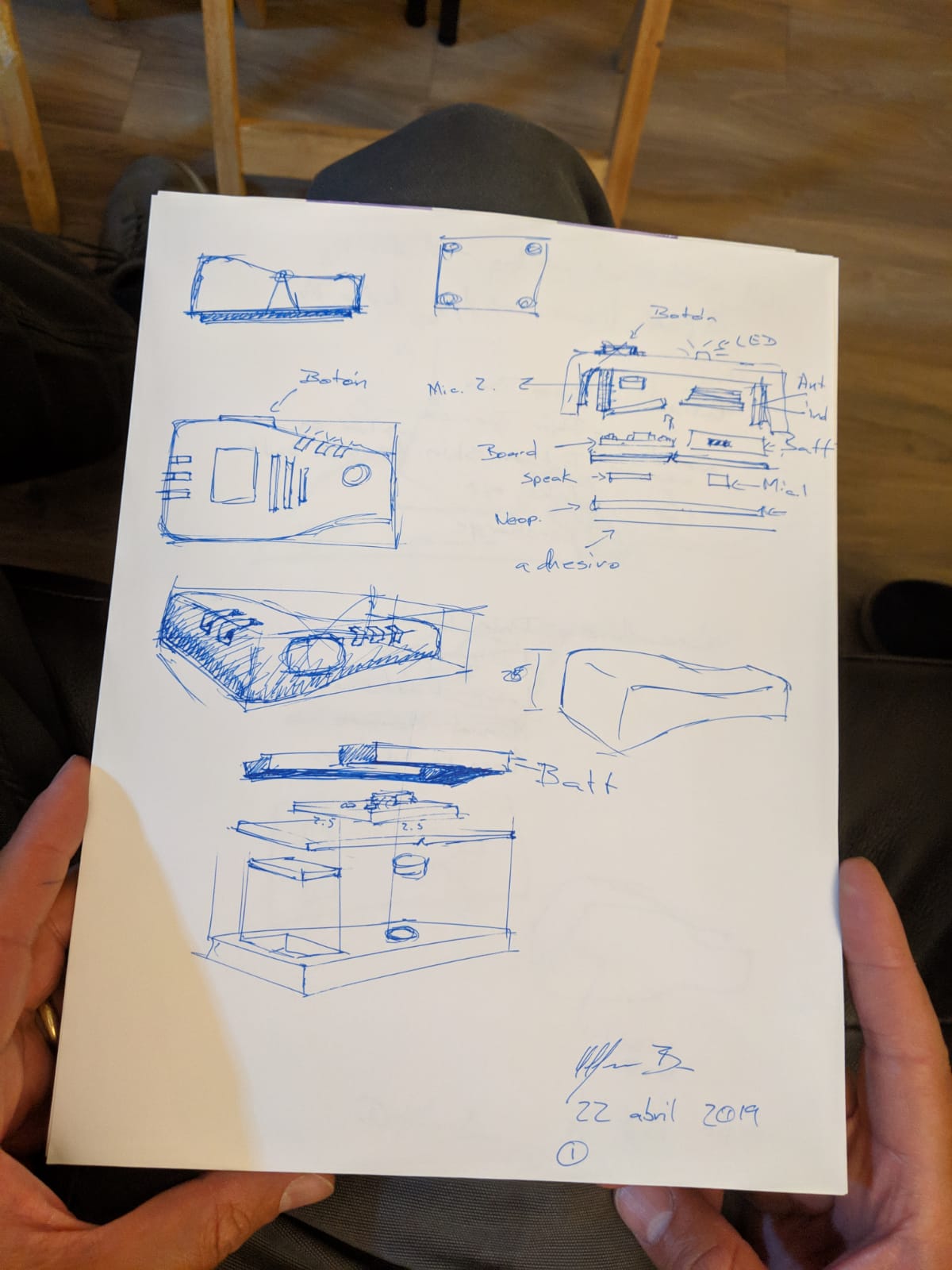

Initial formal sketches

We were focusing on a compact device that will be attached to the patient for long periods of time while continually monitoring respiratory rate and air trapping. The first designs were a single body with both sensors and electronics under the same shell

|

|

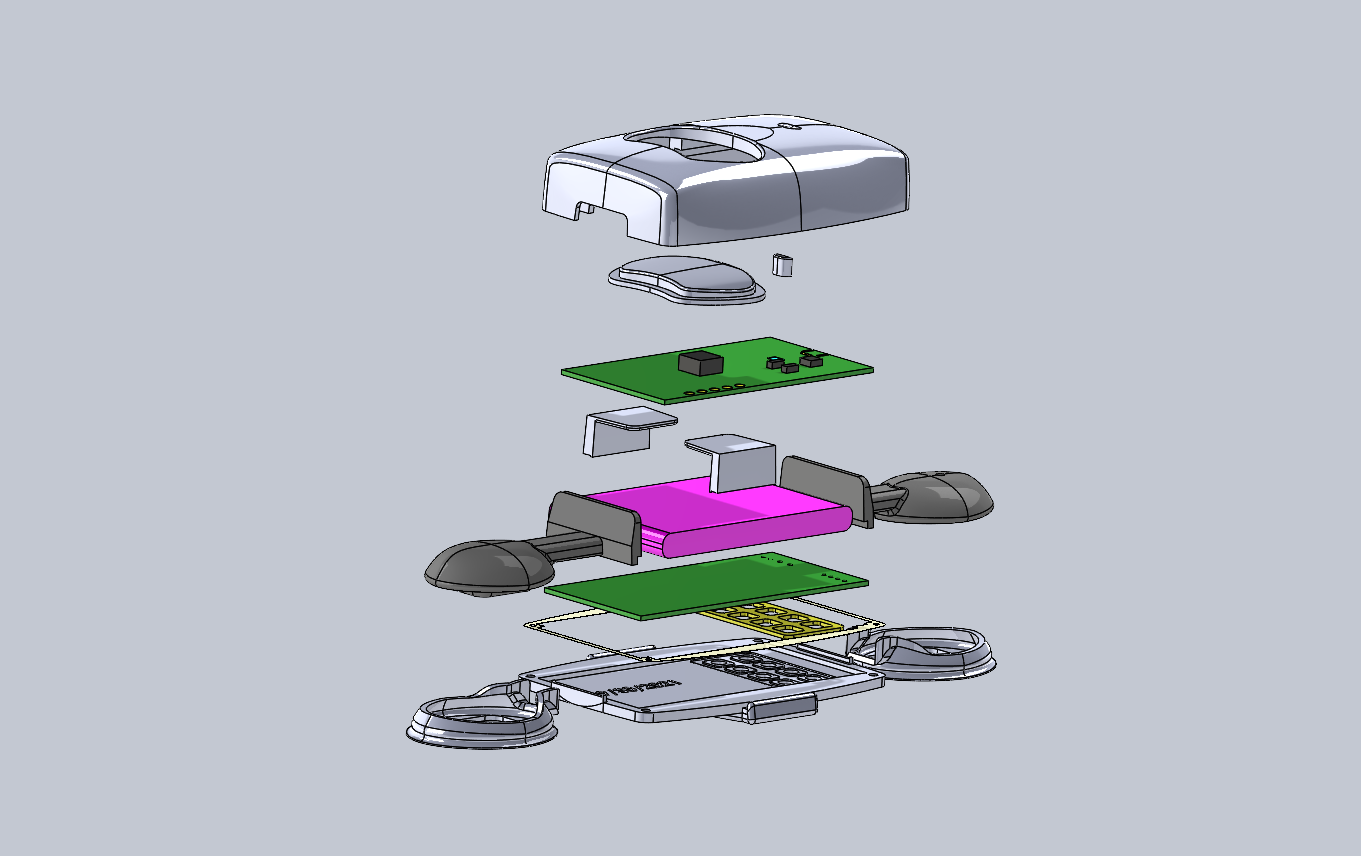

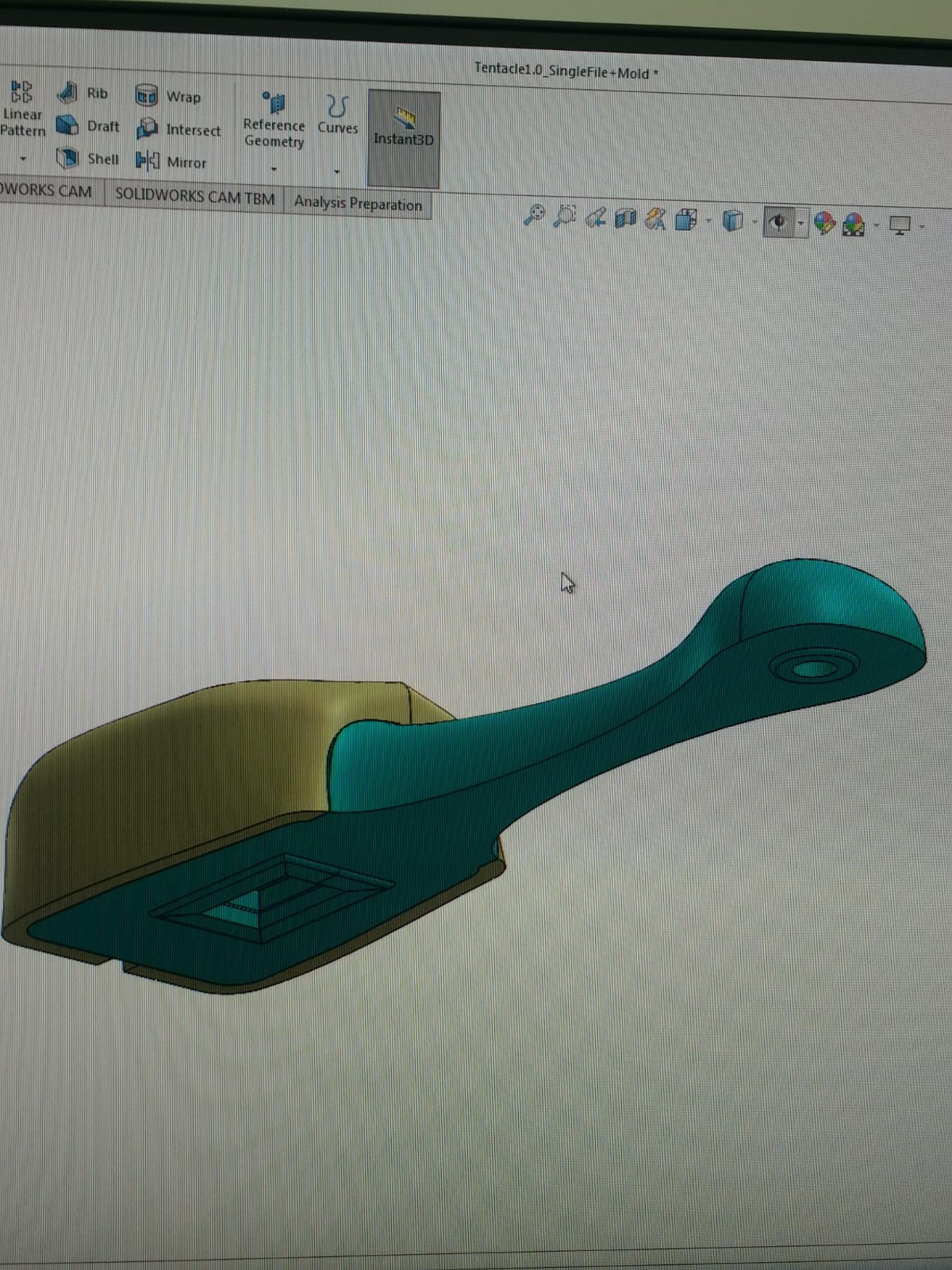

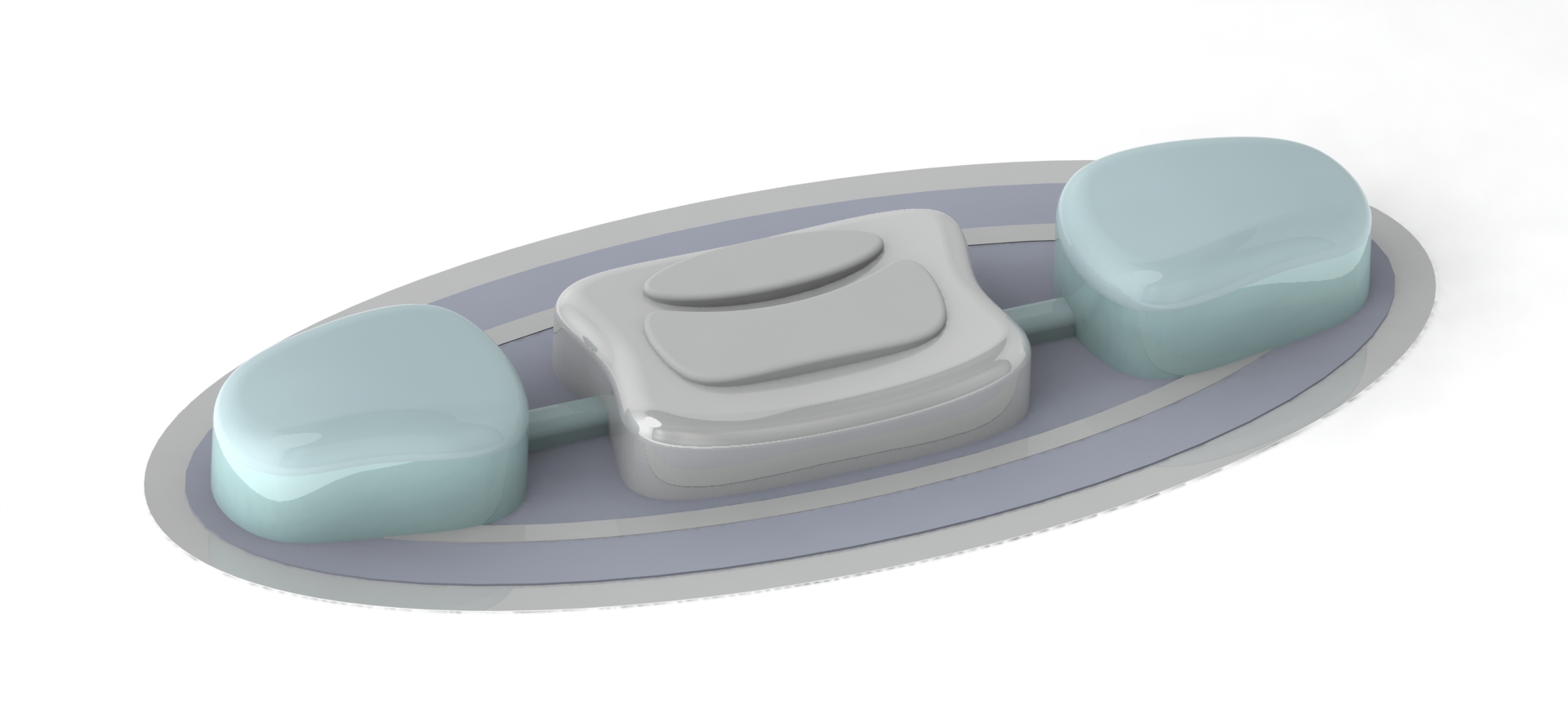

CAD Iterations

We quickly realized in initial tests that the device will not be as compact as we hoped since there is a minimum distance between the speaker and the microphone to make sure that the mic pick up only the resonance through the lung and not the sound directly through the air.

In this design, I wanted to have a single shell with electronics, battery and speaker and extend, with flexible material, an arm for the microphone.

|

|

First Prototype

This was the first prototype to be built and tested. The hard components were 3D printed on PLA while the soft components were casted silicone with 3D printed molds. The electronic components were under the shell and the sensors were encapsulated in the silicone.

|

|

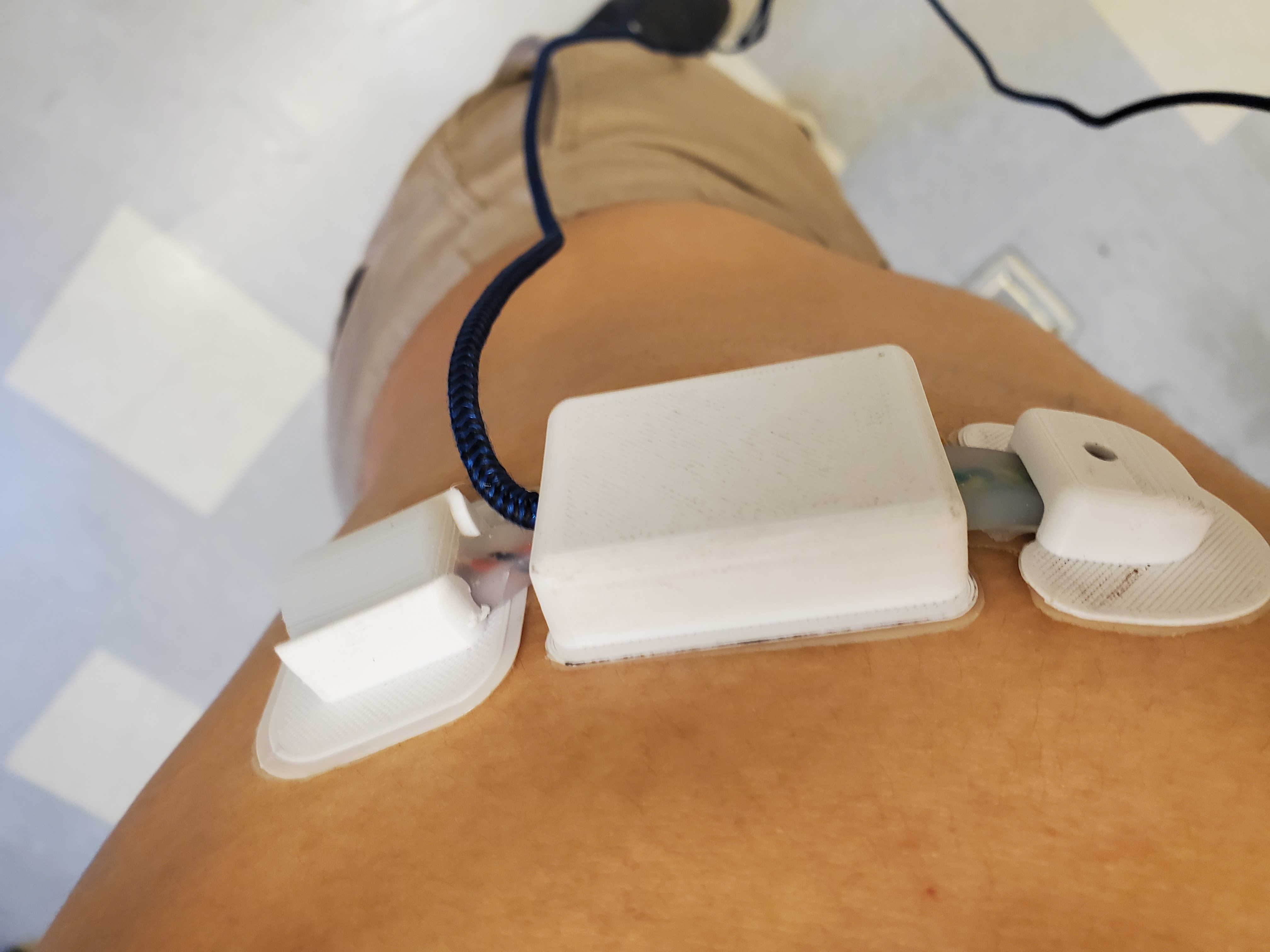

Field Tests

Here is one of our first test in the field with volunteer COPD patients.

|

|

Version 4.0

As the device was now longer than we expected, the design changed to have 3 distinct bodies so that it would better curve around the body.

|

|

Always testing

Our second prototype was built and tested on volunteer patients.

|

|

Evolving the Design

By now the device was working as expected we just needed to fix a few bugs. But the biggest concern was now the comfort of the patient. The device was cumbersome and it was hard for the adhesive to maintain the proper seal.

|

.png)

|

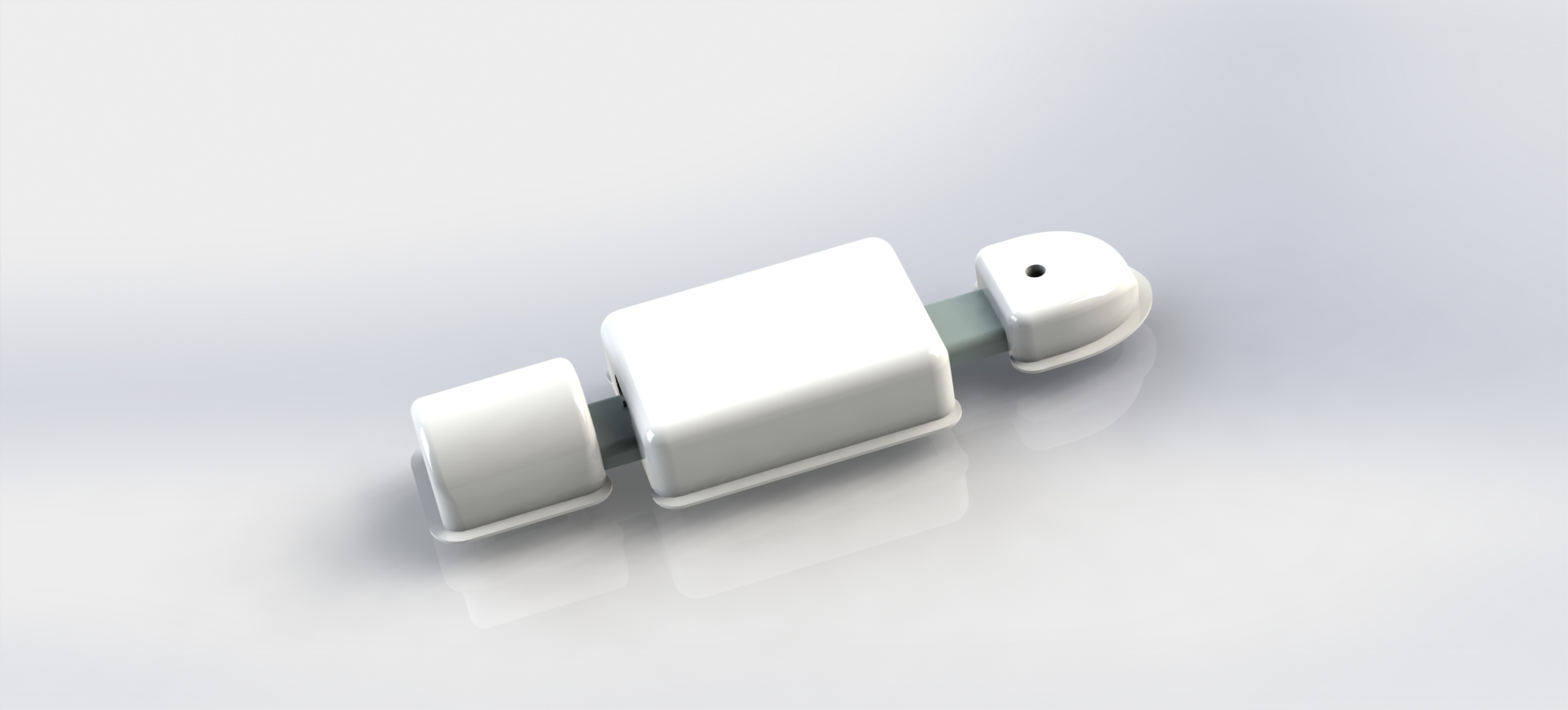

Version 5.0

This version fixed many of the comfort issues and was successfully tested in the field.

|

|

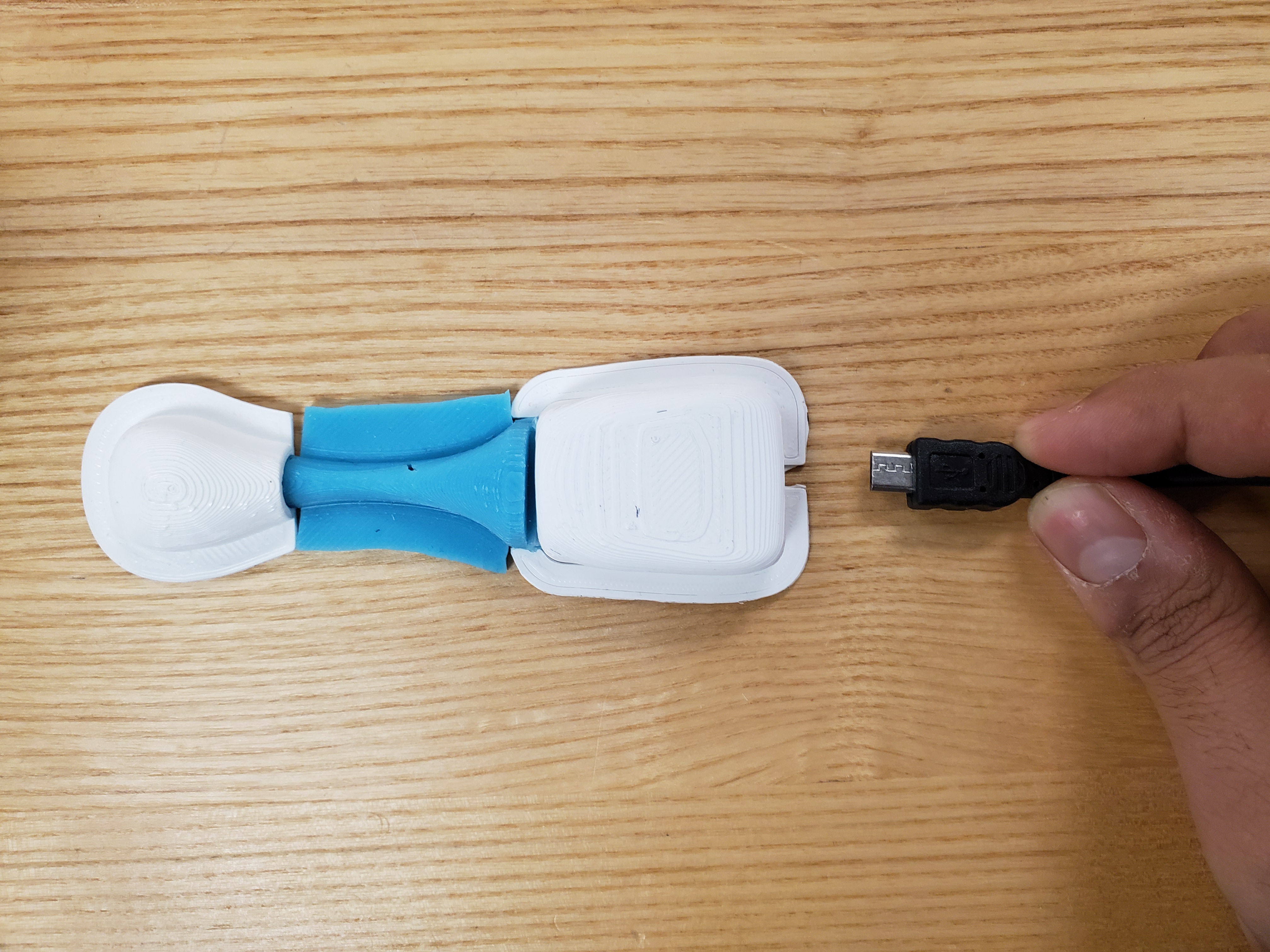

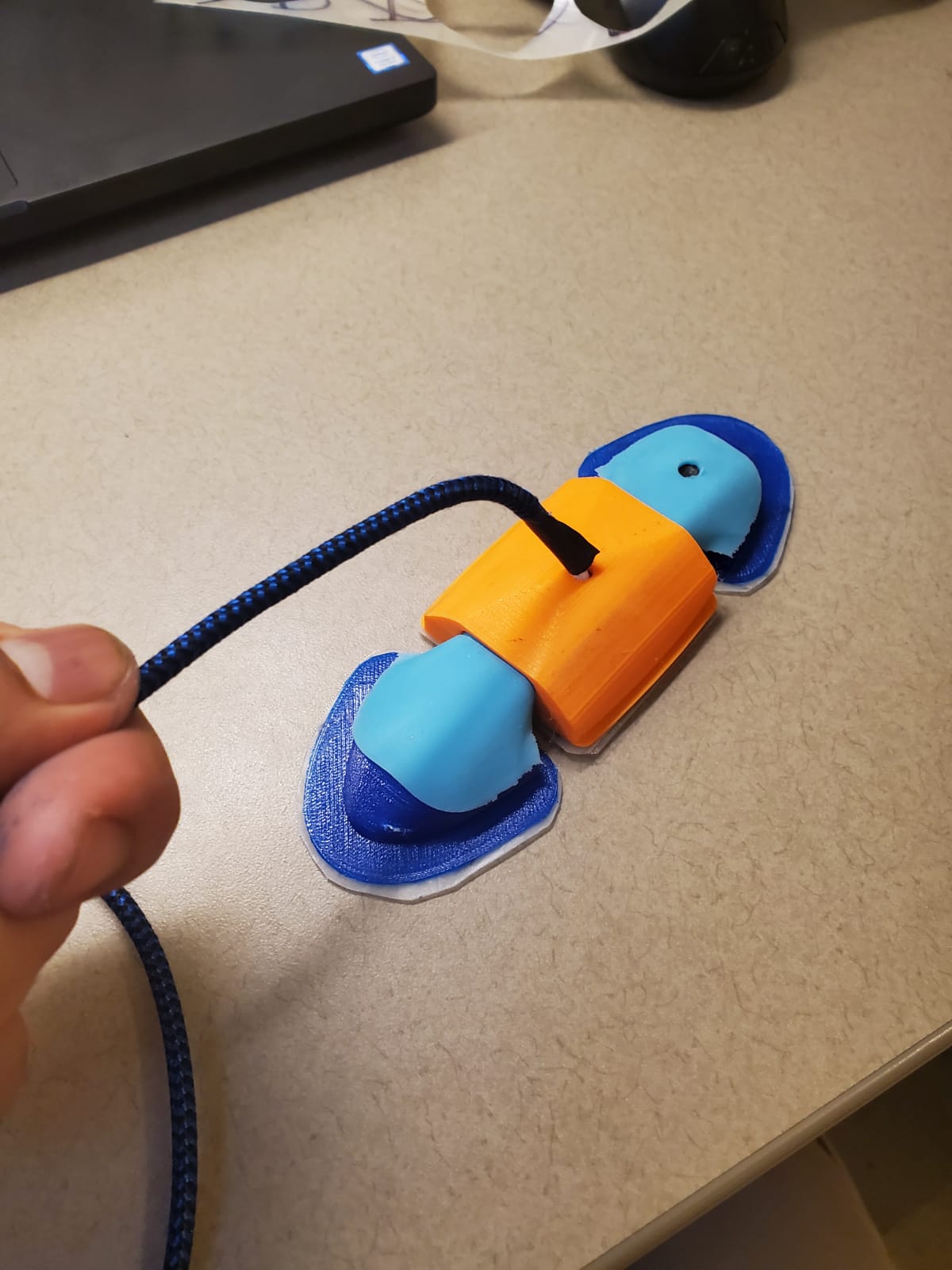

3D printed

The physical prototype.

|

|

Electronics

A view of early electronic components fit inside the prototype. In later models we added a battery and Bluetooth capabilities to make the device fully wireless.

|